But what even more important is the fact that every medical appliance may be customized for the needs of a patient. And thanks to the growing accessibility of the technology, doctors won’t have to wait for months for a medical product to be made somewhere and shipped to them; they may just print it in the clinic if possessing the proper design files.

The demand for the technology is apparent: the global market for 3D printed medical devices is expected to grow from $1.7 billion in 2021 to $4.9 billion by 2026.

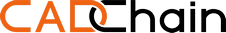

Technavio forecasts the global 3D printing medical devices market to grow at a CAGR of more than 23% by 2023. (Graphic: Business Wire)

While the development of the industries goes fast, new and unknown challenges are emerging.

The first one is the protection of medical designs. The second is the question of design ownership throughout the supply chains and determining the liability at a specific time.

Security-related issues

As every 3D printed medical device is customized, CAD files needed to produce it contain patient-specific data. This happens because the design of, for example, a dental bridge is unique for a person, thus should be protected as any medical information of a human being.

Like any digitally transferred and distributed technology, IP-ownership protection is vital for the industry. Same as with any other CADs, a digital model of a device needs to be manufactured somewhere, and as always, it is essential to track how the product goes through the whole process. And in this case, tampering with the design at any stage may be critical for somebody’s health or even life.

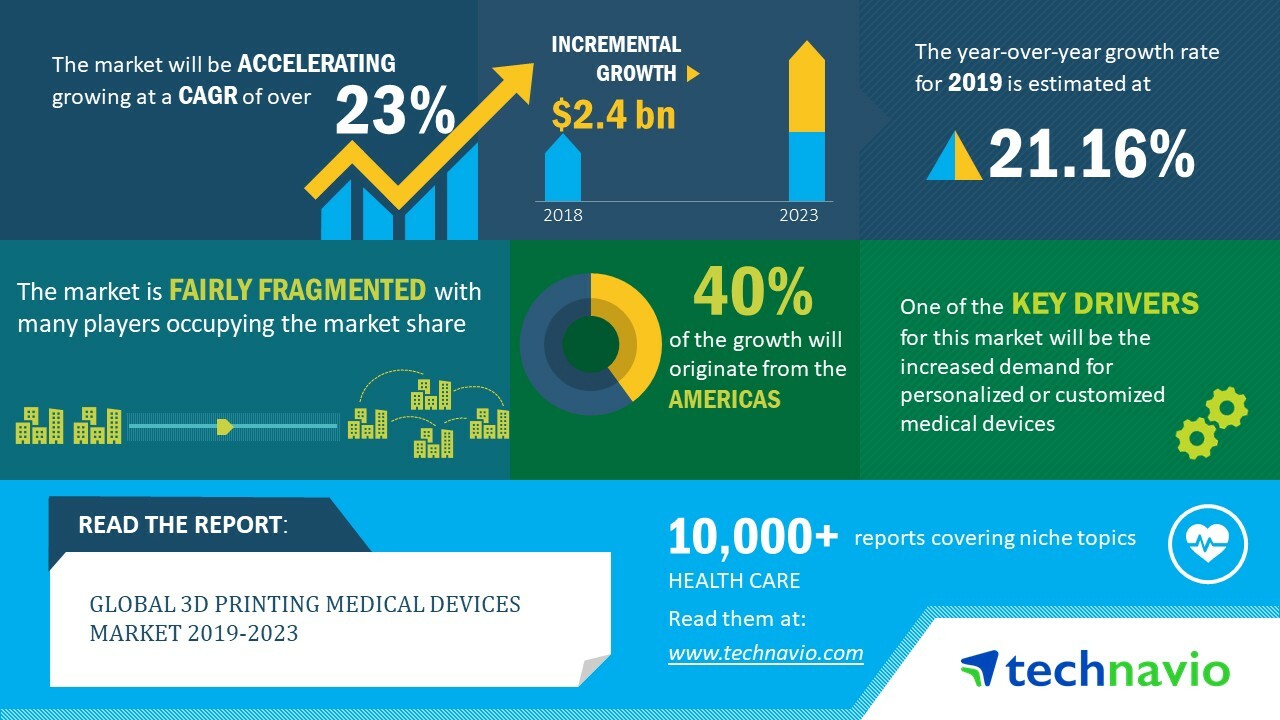

According to HIPAA Journal, there have been more than 900 healthcare hacking incidents between 2018 and 2020 in the US alone. This resulted in more than 40 million medical records being exposed in the incidents. This is the context in which the medical 3D-printing industry operates.

Healthcare Hacking Incidents by Year

Additional risks related to CAD files in the sphere include the acquisition and transfer of personal data and the liability of designers and software engineers.

Product liability issues

Product liability issues arise when damage or injury is caused by a product. And in case of a potential lawsuit, one needs to figure out what party in the supply chain is liable for a specific part of the design.

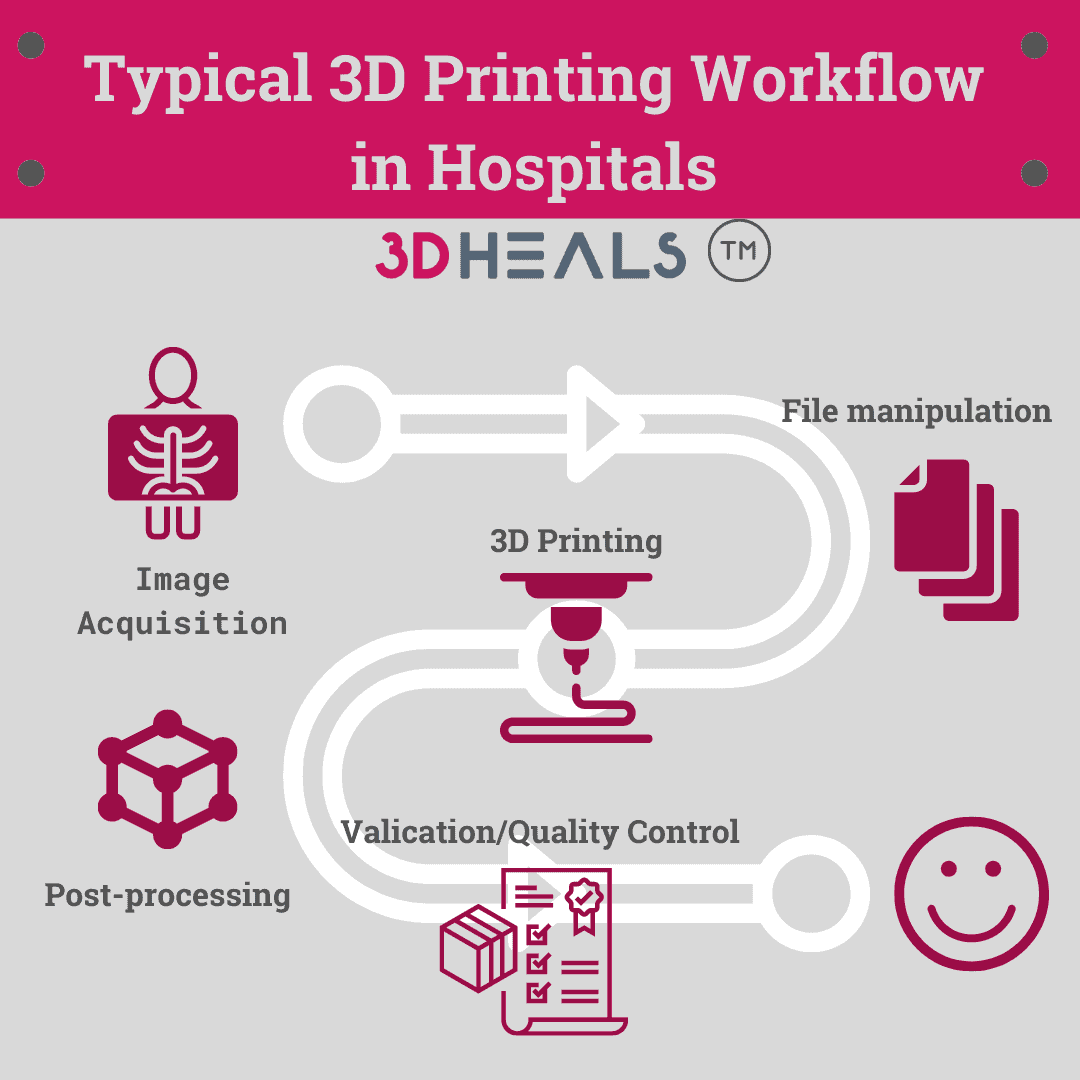

Typical Workflow for 3D Printing in Hospitals

So not only encryption and protection of CAD files is essential but ownership and transferring ownership and figuring out who is the owner at any given point in time. The traceability. Or the problem may come if the customer is the actual DIY manufacturer. 3D printers are getting easier to buy for a regular person, thus comes the risk of people using them to print and use medical appliances without consulting a specialist. This means a wide range of players such as the designer, the manufacturer, and the person who created and used an untested product. And because of such decentralization, there might be potentially catastrophic liability responsibilities and associated regulatory challenges.

How CADChain addresses the abovementioned issues

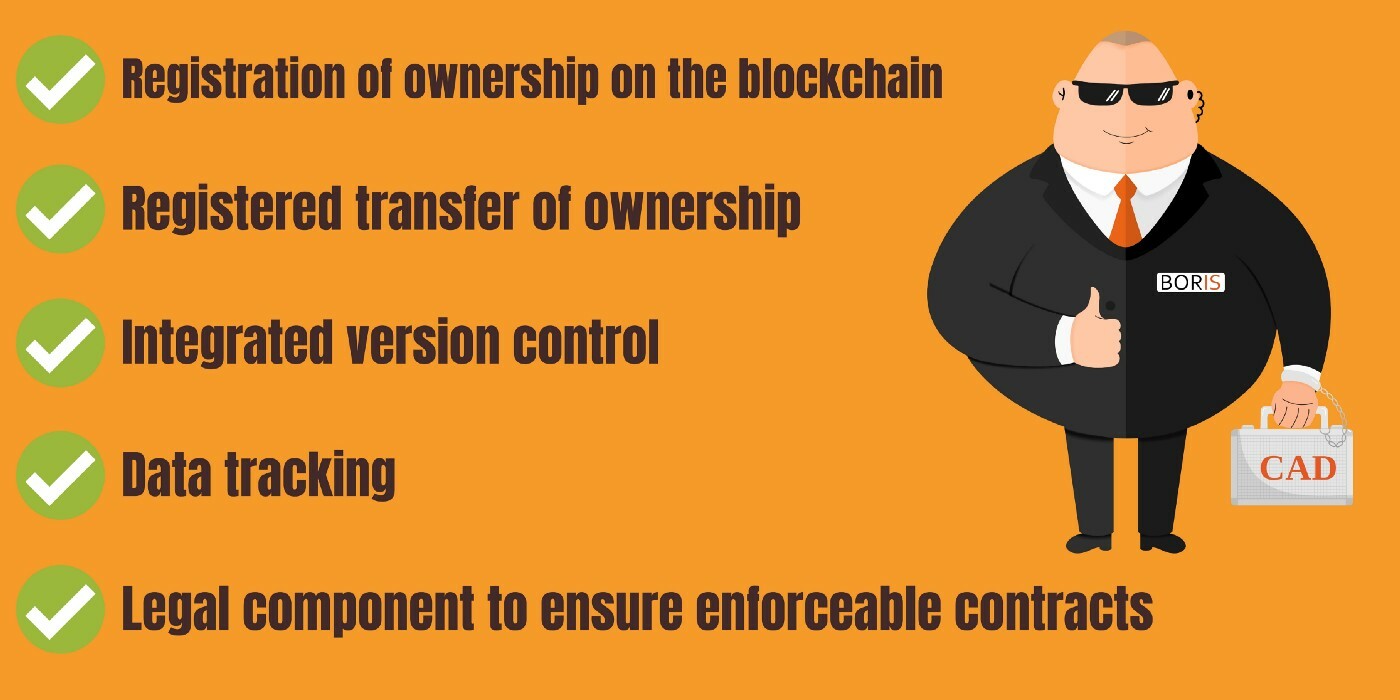

In terms of data protection, CADChain is developing BORIS — a solution for CAD data protection.

We analyze the geometry of a CAD model and create a geometric twin of the CAD file on the blockchain, making it entirely traceable and protected. We do not put your file at risk, though, as all operations all over the supply chain are carried out with the geometric twin, while the original file is safely located in storage of your choosing. But it is essential to be able to regulate what party owns the CAD file in a certain period and what changes it makes with the design.

The solution is not only about encrypting CAD files with a specific digital key tied up to you as an IP owner. It is also about solving the liability problem. As every block with the twin of your file corresponds to the other blocks, it is possible to track all changes made on the CAD file as they are recorded on the blockchain.

Though tracking is helpful, it is not enough to solve the liability problem. Every time a geometric twin is transferred from one participant of the production chain to another, there is a smart contract involved. The contract transfer liability immediately when received and agreed upon by parties with no additional patenting required. So the designer who made the initial CAD file cannot be held responsible for poorly-made production or incorrect application. But at the same time, the contracts allow determining what party is responsible for a particular stage of work and the time limits in which they worked on the product.

So, the solution in the form of a plugin and management interface provides secure CAD data sharing, tracking, and IP protection. It provides access restrictions, and the legal component that handles licensing and any restrictions the owner wants to enforce. So BORIS handles the security of CAD files required for printing a medical appliance and carries all paperwork on his digital but broad shoulders. Try our product BORIS for Fusion 360 to empower your 3D designs protection.

Visit our website www.cadchain.com and request a free trial.