From weapons of the early Stone Age to today’s giant machines, manufacturing meant progress. The emerging Industry 4.0 has accelerated the digitization of customer and supply-chain relations and reshaped many businesses.

All the industrial revolutions were powered respectively by steam, electricity, and technologies like electronics or computers. This led to an exponential growth in efficiency, productivity, output, and prosperity.

But improved standards of living come at the cost of excessive exploitation of natural resources. Deforestation, desertification, pollution of water sources, the threat of climate change, and other ecological issues are the reverse side of the progress.

According to a United Nations report, the Fourth Industrial Revolution (4IR) can contribute to finding new ways of dealing with global challenges. New technologies can boost sustainable development in many sectors, as it allows manufacturers to produce goods through environmentally-sound processes. This will help minimize environmental impacts while saving resources and energy.

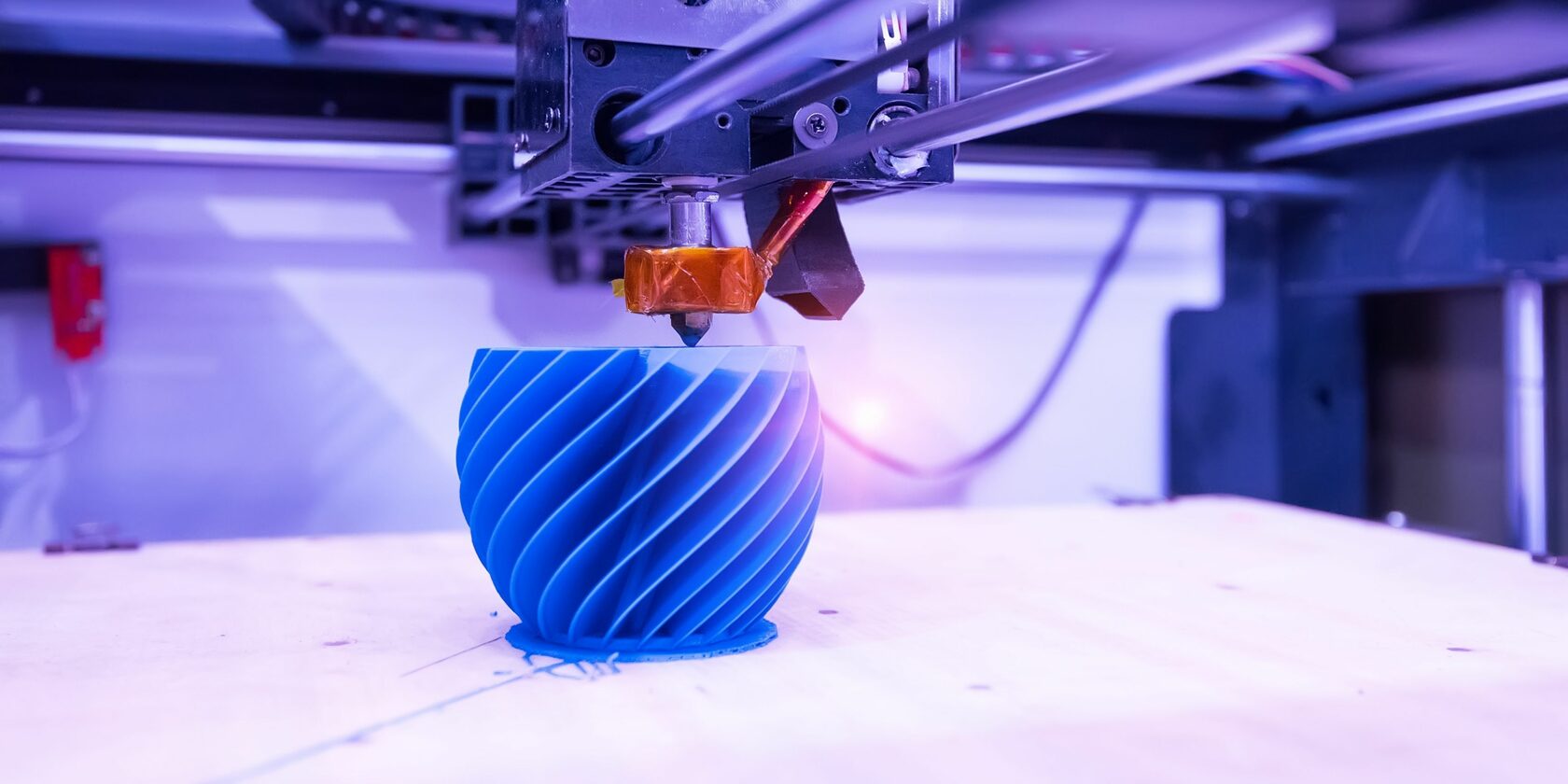

3D printing for greener manufacturing

The most obvious step to take here is to operate processes in an energy and materials-efficient manner. This step is universal for any industry but it never hurts to remind people about it.

Producing something means assembling products out of materials that may leave waste when used. Add logistics to it with all the amounts of fuel burnt while delivering things.

4IR offers an easier solution here — 3D printing. The technology uses computer-aided design (CAD) files to build an item layer by layer in a very precise fashion.

Initially, plastics and metal powders were used as construction materials in the process, but now, they can run on resins, graphite, carbon fibers, or even graphene.

3D printing has many advantages over traditional methods: easy prototyping, increased efficiency, and reduced production costs. According to a research, the technique uses 41% to 64% less energy than traditional production.

3D printing, also known as additive manufacturing, helps reduce supply chain challenges by using light materials. So where a typical wall may be constructed of wood, drywall, screws, tape, mud, and other materials, a 3D-printed one will be made of powder. It is easy to transport, and with the necessary equipment, it is possible to organize production anywhere.

Still, it is likely that in the future, manufacturing will be a blend of traditional methods and additive manufacturing. But 3D-printed items often require supports made of regular materials. They help prevent deformation when an object is in the making but ways of disposing them should be considered to make the process sustainable.

Smart factories

The Internet of Things (IoT) has been around for a while already, but here comes another stage in its development — the Industrial Internet of Things (IIoT). It presents manufacturing industries, with the opportunity to improve their sustainability across all kinds of processes. IoT technologies can monitor how much power a machine is using, adapting it to a particular situation.

Another IoT application in manufacturing is predictive maintenance which means fixing a machine, before it fails. For example, if a machine is consuming too much power, it may be a call for maintenance. By promptly collecting data on when and how the machine is used, the operator can optimize its working schedule. This will also help the environment by lowering power intakes.

Smart food production

Many countries are closing in on their renewable water resource limits. According to the World Bank, 70% of the world’s freshwater is consumed by agriculture. People and industry use two times less water for their needs. Wasteful field application methods are also fairly common with something as trivial as leaking pipes being the major source of waste.

The Industry 4.0 methods can help here too. Using IoT-based technologies, such as soil moisture sensing systems, farmers can ensure that crops get enough water. This also opens many ways for automation, as computer-controlled sprinklers may be set to water crops only when required. These apparently small optimizations can help a lot in reducing water waste.

The Industry 4.0 technologies and sustainability go hand in hand, providing commercial success while staying greener, more efficient, and cost-effective than the traditional ones.